Clean Factomation Introduces Stocker System: A Revolutionary Automated Carry-In/Carry-Out Solution for Efficient Item Storage

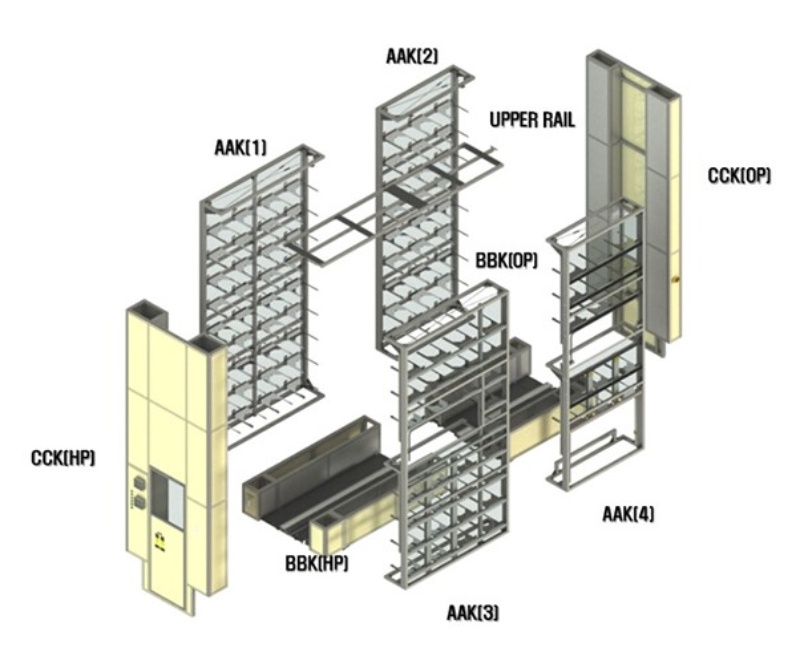

Clean Factomation, the global leader in Automated Material Handling System (AMHS) solutions, proudly unveils its latest innovation, the Stocker System. This state-of-the-art automated carry-in/carry-out system is designed to streamline item storage processes across various industries, setting new standards for efficiency and automation.

The Stocker System provides a fully automated solution for storing items, eliminating the need for manual handling. This results in significant time savings and increased operational efficiency for manufacturing facilities.

Clean Factomation understands the diverse needs of different industries. The Stocker System offers a flexible configuration, allowing businesses to customize it to their specific storage requirements. From small electronic components to larger items, the Stocker System adapts to various sizes and shapes.

Leveraging advanced technology, the Stocker System optimizes storage space with its high-density design. This ensures that businesses can maximize the utilization of their storage facilities, reducing the overall footprint of the system.

The automated carry-in/carry-out mechanism of the Stocker System enables quick and precise retrieval of stored items. This enhances the speed of manufacturing processes and minimizes the risk of errors associated with manual retrieval. Clean Factomation prioritizes user-friendly interfaces, and the Stocker System is no exception. Its intuitive control interface allows for easy monitoring, management, and integration with existing manufacturing systems.

In line with Clean Factomation’s commitment to sustainability, the Stocker System is designed for energy-efficient operation. The system optimizes energy usage, contributing to a more environmentally friendly and cost-effective solution for businesses.

“We are thrilled to introduce the Stocker System to the market, marking another milestone in our mission to provide cutting-edge AMHS solutions. This system is a testament to our commitment to innovation, efficiency, and customer satisfaction,” said the company’s spokesperson.

The Stocker System is set to revolutionize the way businesses handle item storage, offering a reliable, automated, and scalable solution for modern manufacturing facilities.

For more information about Clean Factomation and its Stocker System, please visit https://www.cfinc.co.kr/_service/eng/business_semiconductor_stocker.asp.

About Clean Factomation

Clean Factomation is a global leader in Automated Material Handling System (AMHS) solutions, catering to the diverse needs of industries such as semiconductor manufacturing, flat panel display production, and electronic components assembly. With a focus on innovation and sustainability, Clean Factomation continues to shape the future of manufacturing through cutting-edge automation technologies.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No DFHS Newspaper journalist was involved in the writing and production of this article.